The olive trees are everywhere you look — they cover the hillsides of Chianti, line the streets of the small towns, decorate the gardens of the ancient villas and border the vineyards all over this region.

Over the course of our first week here, we have learned the importance of olive oil to the Chianti natives, and have witnessed their passion and pride for the oil they produce here. So far, each winery we have visited has extolled the virtues of their private label olive oil. And our recent cooking class reinforced the benefits of the “first press” and the difference between Extra Virgin and that stuff you buy in a big can at Costco.

Last night we had the opportunity to see why this oil is so valued (and expensive!) when our hosts, Andrea and Lucia, invited us to accompany them when they took their olives to be pressed.

The day we arrived, Andrea explained that we would see him around the property all week harvesting his olives. And every day when we headed out on our adventures, we’d spot Andrea and one of his helpers hand-picking olives, trimming off dead branches and gathering the olives in a large net which was spread underneath the trees so no olives could go astray.

It’s hard, tedious work. And with the days getting shorter, and the weather getting cooler, the locals spend all day in their groves harvesting as much as they can before the first frost.

So last evening, we followed Lucia into Tavernelle, to a grape and olive pressing facility tucked into a side road in what looked like a residential neighborhood. But you could smell the olives a block away.

Lucia explained that the first step was to back the loaded car or truck onto a large floor scale to be weighed. Once the bins of olives were unloaded into a large trench in the floor, the empty bins would be returned to the vehicle, and the car or truck would be weighed again for the “tare” weight. The difference between the two weights would be the actual weight of the olives.

(I’m actually familiar with this part of the process, since my friend Debby does this with truck loads of Concord grapes at the Welch’s production facility in her home town in Pennsylvania.)

The floor trenches where the olives are unloaded have a large auger in the bottom, which moves the olives along into the next machine, and helps separate the olives from the leaves and branches.

The next machine has mesh which allows the olives to drop through, but traps the leaves and branches. We learned from Andrea that those byproducts are compressed and composted by the facility.

Then the olives are sent up an inclined belt for one more separation step before they go through the washing process.

From here, the olives move to the next room where a long, enclosed conveyor belt takes them through a high-pressure washing process. In this room, we spotted a video monitor which the man running the conveyor belt uses to monitor the amount of olives remaining in the big trenches out in the first room.

Andrea and Lucia were as giddy as small children as they watched their olives move through the various stages of this process.

Then, the olives are pressed. Skin, pits and all. (The pressing machine is the tank to the right of Andrea in the photo above.)

And in the final step, the oil is separated from any remaining water in a centrifuge, the paste of the olive skin and pits are discarded, and what is left is this gorgeous, green liquid. Extra Virgin Olive Oil.

(Here you see the paste being spit out into that funnel-looking thing in the back, and the beautiful, green olive oil draining into the bin.)

(Here you see the paste being spit out into that funnel-looking thing in the back, and the beautiful, green olive oil draining into the bin.)

As you can see, we were as excited as Andrea and Lucia!

As you can see, we were as excited as Andrea and Lucia!

From here, the olive oil is sent into a big tank to get a final measurement (weight and acid level — to be classified as EVVO, the acid level of the oil has to be under .3%), then decanted into either cans or large tanks provided by olive grower.

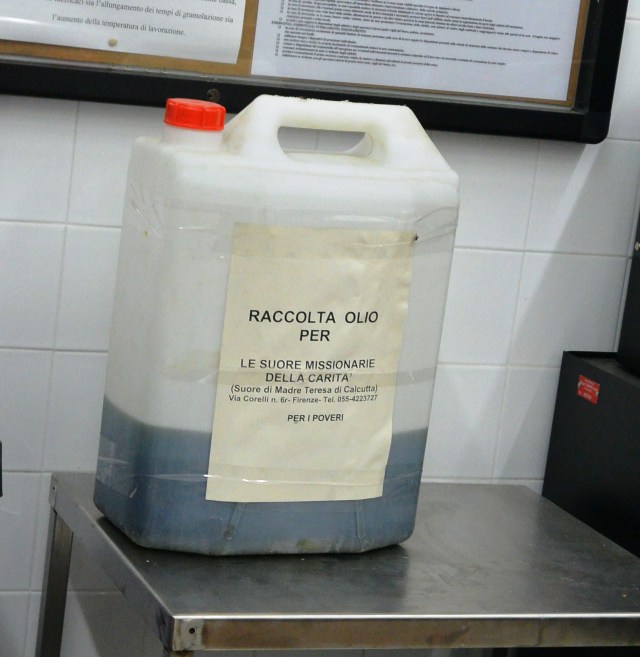

I noticed a large plastic tank on the table behind the other tanks. It had a label on it that I couldn’t figure out, so I asked Andrea to translate for me.

He explained that this was olive oil that would be donated to feed the poor and that each grower who uses the facility donates 10% of their final product. I don’t know if this was a common practice, a local tradition, or just part of the “cost” of having your olives pressed at that facility. But I thought it was very cool.

I also asked Andrea how many of those large tanks he would end up with after months of tending his trees and five long days of harvesting. He told me that he brought in 300 kilos (about 660 pounds) of olives and would probably get about 40 liters (10.5 gallons) when the press was done.

Wow. That’s a lot of effort. No wonder Extra Virgin Olive Oil is so expensive.

A few hours later, when mom, Louise and I were finishing up our dinner back at the villa, we heard a knock on the door. It was Lucia, bearing a loaf of fresh Tuscan bread, a couple of cloves of garlic, and a pitcher of Andrea’s freshly pressed olive oil.

It’s experiences like these that motivate me to travel to new places. While touring in a group has its advantages, there is so much to be said for heading out on your own. I guarantee that those hordes of people we saw walking along the streets of Florence, following the red flags and yellow umbrellas would NEVER have the opportunity to witness the unbounded joy of a small olive oil producer watching his hard work turn into liquid gold.

Ciao!

Such a cool experience! Thank you for documenting your adventures – I am living vicariously through you!! 😀